|

| Multiplate Disc Brakes |

Most modern multi-plate disc brakes run in oil to transfer the

heat away from the friction plates but that hasn’t always been the case.

The enclosed nature of the brake does require consideration of heat dissipation

though. We will only discuss wet brakes here.

There are two fundamental types of multi-plate brakes, servo and non servo.

This page follows the non servo brakes, servo brakes can be found here:-

Multiplate Servo Disc Brakes

The purpose of a multi plate disc brake is the same as the more conventional

caliper. It has to retard, stop and hold the vehicle. The fundamental difference

is that it is self contained and cooled by oil.

In principle it’s not too different to a motorcycle clutch but of course

the details are very different.

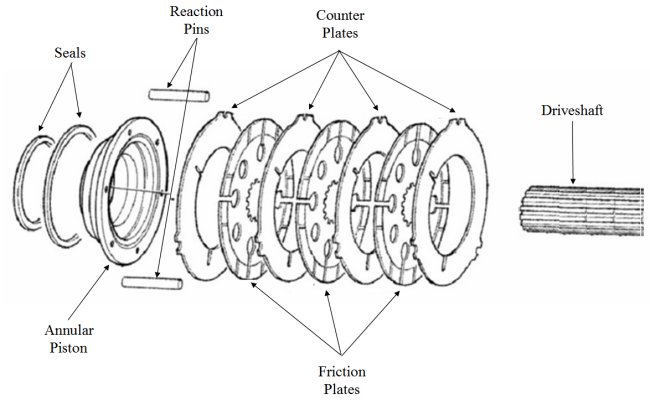

The braking faces are between a number of interleaved friction discs and counter

plates alternately keyed to the housing or splined to a driveshaft. The plates

are clamped together to produce a braking torque either by an annular piston

which is coaxial with the driveshaft or by a ball and ramp mechanism.

Many vehicles using this type of brake have hub reduction gearing so it is common

for oil immersed brakes to be inboard of this gearing and as such they run at

five or six time wheel speed.

Annular Piston Brakes

Annular piston brakes have the benefit of simplicity of construction.

As the piston only moves in an axial direction to load the brake plates there

is no inbuilt servo effect and the brake factor is one. A low brake factor means

that the brake torque between left and right brakes will be more equal (since

differences are not amplified) and the brake system will be more controllable,

for a similar actuation.

On the downside, to get a given torque output a bigger piston will be required

and this together with the long rubber seals (one metre or more) consumes a

greater fluid volume. In order to minimise pedal travel, in none power brake

applications, annular piston brakes run with low clearances and often have a

method of controlling the amount of piston retraction.

Generally this type of brake is manufactured ‘in house’ with only

the plates being bought from a specialist brake supplier.

Ball Ramp Brakes

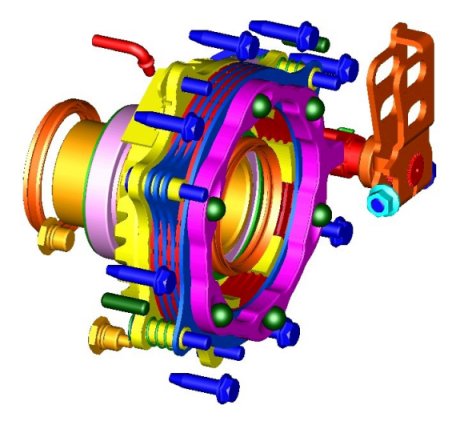

Ball ramp brakes have a mechanism inside the axle however if they are hydraulically applied the actuation is usually accessible from outside which helps to reduce servicing costs. In order to make a ball ramp actuator non servo the actuator must be decoupled from the friction plates. This is best done by using a needle roller bearing but Yamaha use a low friction plain bearing on this ATV brake as an acceptable trade off between performance and simplicity.

Drag Losses

The main difference between a brake and a clutch is that a brake

runs open and a clutch closed. In a brake the clearance between the plates causes

parasitic losses by churning the oil and can consume large amounts of power,

(the same applies to a lesser extent on ventilated dry discs where air pumping

losses can be considerable – The French TGV train runs on solid discs

for this reason).

Power losses reduce as the clearance increases up to about 0.15mm per face but

at this level the fluid volume required to apply the brake would make actuation

difficult.

Running Clearance Control

Running clearances are usually compromises between minimising

power losses and reasonable pedal travels when controlled by a master cylinder.

Power loss curves shows little benefit can be gained from increasing the clearance

above 0.15mm per friction face.

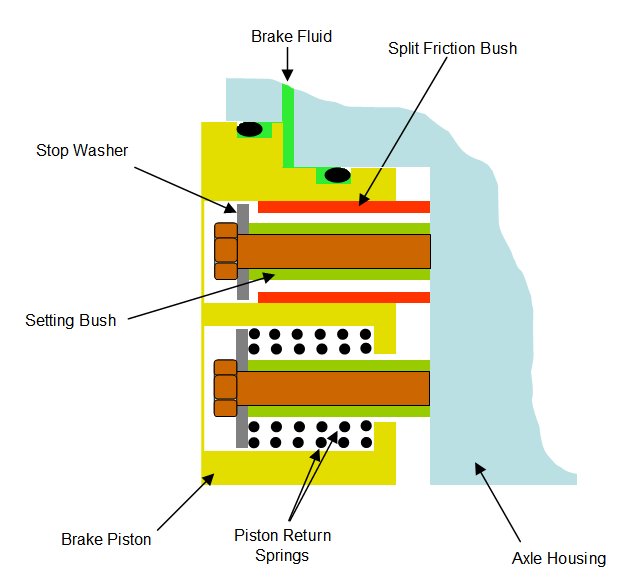

Annular piston brakes often use a controlled back-off mechanism to ensure the

running clearance is maintained as plate wear takes place. This usually consists

of a spring and a friction device.

This is a part section of a Caterpillar annular piston brake showing

one of the, usually three retraction devices.

When the brake is applied brake fluid pressurises the annular area between the two seals and forces the brake

piston to the left, clamping the friction plates to the counter plates

(not shown). If no adjustment is required then the split

friction bush pressed into the brake

piston does not contact the stop washer.

Releasing the brake pressure allows the piston

return springs to reset the brake piston until the end of the split friction bush touches the axle housing.

Should adjustment be required the split friction

bush touches the stop washer before sufficient clamp load is generated on the friction plates, this causes

the split friction bush to be dragged

down its bore. When the brake is released the brake

piston is reset to a new back stop position.

This type of adjuster is not load insensitive and could over-adjust if a high

pressure stop allowed the piston to move beyond its normal position however

given the brake is a full circle and the friction material is very thin the

brake is so stiff as to not require a more complex adjuster.

Friction Material Type

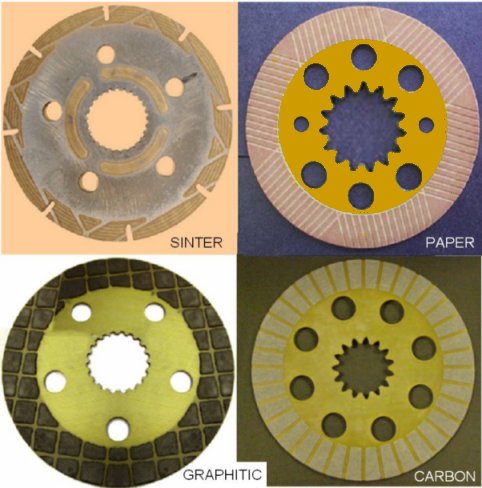

There are four basic types of friction material available each with there own pro’s and cons, sintered, paper, graphitic, carbon.

Sintered bronze is made by sintering a blend of powders into a

porous matrix on a steel carrier plate. It is a tough durable material well

able to live with overheating. On the downside it has a low dynamic friction

and a high static / dynamic friction ratio which can cause chatter noise.

Paper frictions materials are so called because of the manufacturing process

as much as the material itself. They contain a range of fibres and friction

modifiers which are then saturated in resins. The resulting material is soft

and easily damaged. Paper materials have a high dynamic friction level and a

low static / dynamic friction ratio which gives them good torque capacity and

low noise however their energy capacity tends to be low.

Graphitic materials are moulded compositions of graphite and resin binders.

The have good thermal capacities which make them durable however they have a

moderate static / dynamic friction ratio which may make them noisy.

Carbon linings give stable friction, high load and low wear but are very expensive

as such they are rarely used.

Groove Pattern

Grooves are either machined or moulded into the friction material

to aid oil flow and thus cooling. Numerous patterns exist and each friction

plate manufacturer has his favourite however the following points should be

born in mind:-

The oil must be part of the cooling process. If large amounts of oil are present

then the oil can flow quickly through the plates however if supply is limited

then the flow through the plates should be restricted. Oil trapped between plates

increases the parasitic drag losses and causes oil heating during brakes off

running.

Spiral - This grooving pattern may be used where there is limited oil available

due to the design of the brake. The spiral pattern gives controlled oil

flow through the grooves but will give high viscous drag.

Radial - or sunburst pattern is suitable for applications in which sufficient

oil is available. It facilitates high oil flow and quickly disperses heat

whilst minimizing viscous drag.

Waffle - or multiple pass patterns are compromises between spiral and radial

and offer some oil flow restriction without increasing drag too much.

© Engineering Inspiration